Project Overview:

Precise angle measurement of seatbelt mechanism covers is critical in ensuring functionality and safety. The current manual inspection process is time-consuming, prone to errors, and inefficient. To overcome these challenges, an AI-based vision inspection system was proposed for high-precision, automated angle inspection.

Problem Statement:

The manual process of checking seatbelt mechanism covers for angle verification is very inefficient, prone to human error, and doesn’t provide exact measurement in order to fulfill quality and safety standards.

Advanced reliable inspection system that will enable accuracy and diminish the inspection time is what is being proposed as the solution for this problem.

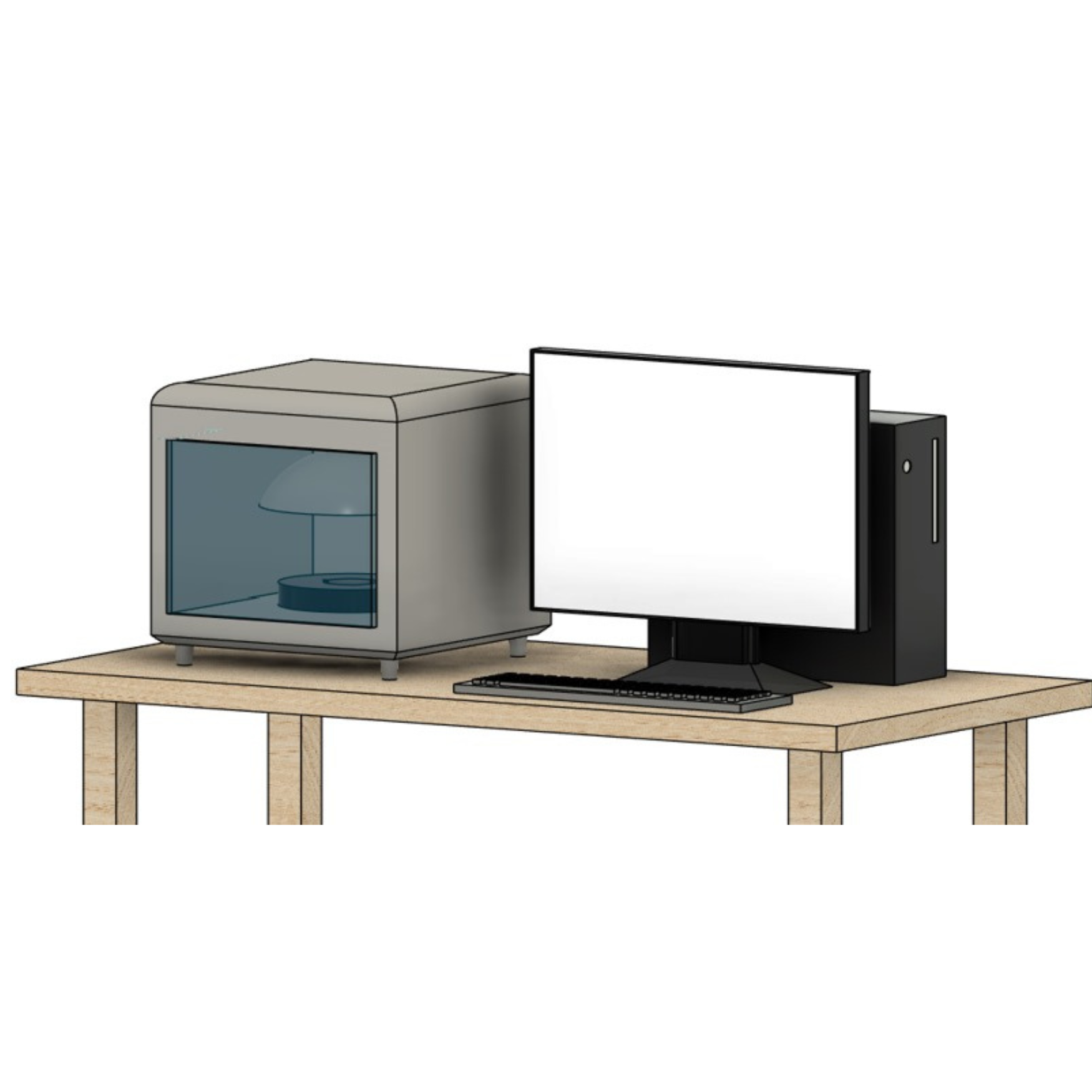

An AI-based vision inspection system was designed to automate the angle inspection process. This system uses high-resolution cameras and AI algorithms to provide real-time detection, measurement, and quality control of the seatbelt mechanism covers.

Impact:

The AI-driven solution delivered significant improvements:

Quality Control: Consistent product quality and reliability ensured superior safety standards.

Accuracy: Precise angle measurement and defect detection.

Efficiency: Reduced inspection time, allowing for faster production cycles.

Operational Efficiency: Automation reduced human dependency and improved overall productivity.